The rapid advancement of Artificial Intelligence (AI) technology has led to an exponential surge in its computational demands. Whether it’s training vast neural network models or performing complex inference calculations, powerful hardware is essential. However, high computing power invariably comes with high power consumption and heat generation. Traditional air-cooling solutions are increasingly showing their limitations when faced with the rising power density of AI chips. Liquid cooling technology, with its superior heat dissipation capabilities, is becoming a crucial component of AI computing infrastructure. And within liquid cooling systems, the precision of AI liquid cooling connectors is paramount, directly impacting the stable operation, cooling efficiency, and long-term reliability of the entire system.

The Urgent Need and Challenges of AI Liquid Cooling

AI chips, especially GPUs and specialized AI accelerators, generate significant heat during operation. If this heat cannot be dissipated effectively and promptly, it will not only lead to performance degradation (thermal throttling) but can also damage the hardware due to overheating. Liquid cooling, by using liquid as a heat transfer medium, can transfer heat from heat-generating components to the heat dissipation end much faster and more efficiently than air. Its cooling efficiency far surpasses that of air cooling.

However, the complexity of AI liquid cooling systems introduces new challenges. Numerous liquid cooling pipes, connectors, and heat dissipation components form a sophisticated fluid network. Negligence in any part of this network can lead to leaks, blockages, or reduced cooling efficiency, consequently affecting the stability and performance of the entire AI system. Particularly at the critical connection points between various components – the liquid cooling connectors – their precision becomes exceptionally important.

The Connotation of Precision in AI Liquid Cooling Connectors

The precision of AI liquid cooling connectors is not merely about the accuracy of their physical dimensions; it encompasses several key aspects:

-

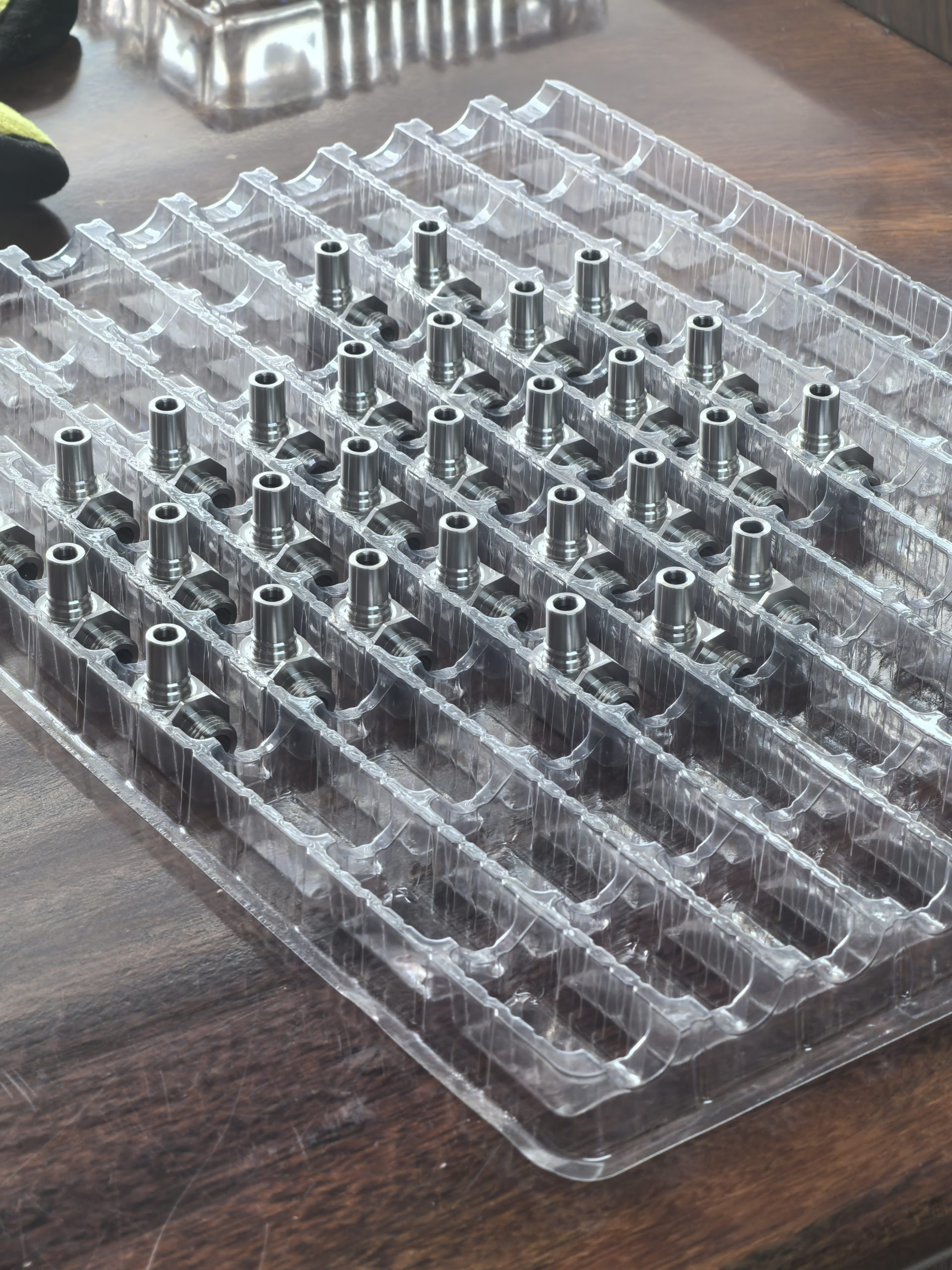

Dimensional Accuracy and Compatibility: Liquid cooling connectors need to establish tight connections with pipes, cold plates, pumps, and other components. Even minute dimensional deviations can result in insecure connections and the risk of leaks. Therefore, the inner diameter, outer diameter, thread dimensions, and the flatness of sealing surfaces of the connectors must achieve extremely high precision to ensure perfect compatibility with mating parts.

-

Sealing Performance: The coolant in liquid cooling systems often has a certain degree of corrosiveness, and the system operates under a certain pressure. The sealing performance of the connectors directly determines whether the system will leak. High-precision connector design and high-quality sealing materials are crucial for ensuring zero leakage. This requires strict control over the surface finish of the contact areas, the material and dimensions of the O-rings, and the reliability of the connection structure.

-

Fluid Resistance: The cooling efficiency of a liquid cooling system is closely related to the flow of the coolant. Precisely designed connectors should minimize fluid resistance to ensure smooth coolant flow. Improper internal structure design, burrs, or sharp edges can increase fluid resistance, reduce cooling efficiency, and even lead to localized overheating.

-

Pressure and Corrosion Resistance: AI liquid cooling systems experience pressure fluctuations during operation, and the coolant may contain additives to enhance heat transfer performance or inhibit microbial growth. Therefore, liquid cooling connectors must possess sufficient pressure resistance and good corrosion resistance to ensure long-term stable operation. This necessitates the selection of appropriate materials and precise manufacturing processes.

-

Ease of Installation and Reliability: During the deployment and maintenance of large-scale AI clusters, liquid cooling systems are frequently installed and disassembled. Precisely designed connectors should be easy to install, simple to operate, and provide reliable connections, reducing the risks associated with human error. Quick-connect and self-locking designs can significantly improve installation efficiency and reliability.

The Role of Precise AI Liquid Cooling Connectors in Driving Future Computing Power

High-precision AI liquid cooling connectors are a vital guarantee for driving the future of AI computing power. Their role is evident in the following aspects:

- Enhanced Cooling Efficiency, Supporting Higher Power Density: Precise connectors ensure smooth coolant flow and good contact with heat dissipation components, thereby maximizing the cooling advantages of liquid cooling. This supports the stable operation of higher power density AI chips, unlocking greater computing power.

- Ensured System Stability, Reduced Maintenance Costs: High-precision sealing performance and reliable connection structures effectively prevent failures such as leaks, reducing system maintenance costs and downtime risks, and ensuring the continuous and stable operation of AI systems.

- Optimized Energy Efficiency, Lower Operating Costs: Efficient cooling reduces the energy consumption of the cooling system, thereby lowering the overall operating costs of AI infrastructure, aligning with the trend of green computing.

- Promoted Technological Innovation, Driving AI Development: Reliable and efficient liquid cooling solutions provide greater design and manufacturing freedom for AI chips, which can drive the research and development of higher-performance, more integrated AI chips, accelerating the advancement of AI technology.

Conclusion

In the era of rapid AI development, the relentless pursuit of computing power makes liquid cooling technology an indispensable critical component. As a vital part of liquid cooling systems, the precision of AI liquid cooling connectors directly impacts the performance and reliability of the entire system. Only through precise dimensional control, excellent sealing performance, optimized fluid design, and reliable material selection can we create liquid cooling systems capable of meeting the demands of future AI computing power. It is foreseeable that with the continuous evolution of AI technology, the demand for high-precision AI liquid cooling connectors will become even more pressing, serving as a crucial force driving the sustained growth of future computing power.

Prelucrare CNC pe cinci axe, prelucrare CNC de precizie, prelucrarea strungului, Prelucrare de strunjire și frezare, frezare prelucrare pe cinci axe

Prelucrare CNC pe cinci axe, prelucrare CNC de precizie, prelucrarea strungului, Prelucrare de strunjire și frezare, frezare prelucrare pe cinci axe