1. The whole machine has a compact structure, beautiful appearance, and a sense of the times. Excellent configuration is a reliable guarantee of high precision, fast speed, and good stability. The bed and crossbeam of the entire casting are formed through secondary high-precision machining. Good overall rigidity, precision, and performance stability.

2. Bilateral dual communication servo motor (imported) synchronous drive, running smoothly. And equipped with imported high-precision disc reducer and matching helical gear and rack motion mechanism. Ensure high accuracy and fast operation speed: positioning accuracy ± 0.025mm/m, repeated positioning accuracy 0.015mm. The operating speed is 120m/min. Compared to similar products, it can improve production efficiency by 30%.

3. Multiple auxiliary functions, good operability, and convenient maintenance: fully enclosed light guide system and flying light path, drawer quick change mirror holder ensure the cleanliness, lifespan, and cutting accuracy of the lenses. Large Longmen Grinding Machine

4. Large CNC machining control console, simple and clear, with a suitable height and viewpoint for ergonomics, moderate height, and convenient operation. The imported ball linear guide adopts fully enclosed protection to reduce dust pollution, improve the service life of transmission components, and ensure smooth operation.

5. The large CNC machining structure is simple and easy to adjust. The laser cutting head can accept a gas pressure of 2.3Mpa. Adjusting gas pressure can be applied to cutting various thicknesses and materials of boards. The laser cutting head is also equipped with an imported capacitive high-sensitivity non-contact tracking system, which ensures strict consistency between the cutting system and the sheet metal. Ensure accurate cutting quality and avoid damaging the laser cutting head due to collision with the board.

6. The central pneumatic components of the integrated pneumatic control system are all imported parts. Plan an advanced gas path control system that can simultaneously connect three different auxiliary gases and actively convert them. The advanced planning of high-pressure gas paths has improved the cutting ability and quality of difficult to cut materials such as stainless steel.

7. Multi focal length 5 “and 7.5” focusing lenses have quick replacement function (fully satisfied with high-quality cutting of thin and thick plates), and can replace plates of different thicknesses at any time. Shorten the replacement time of the gathering mirror and improve the effective working time.

8. The fully enclosed concealed waste lubricating oil collection system and partitioned smoke exhaust and dust removal system aim to minimize pollution to the bed and surrounding air and environment.

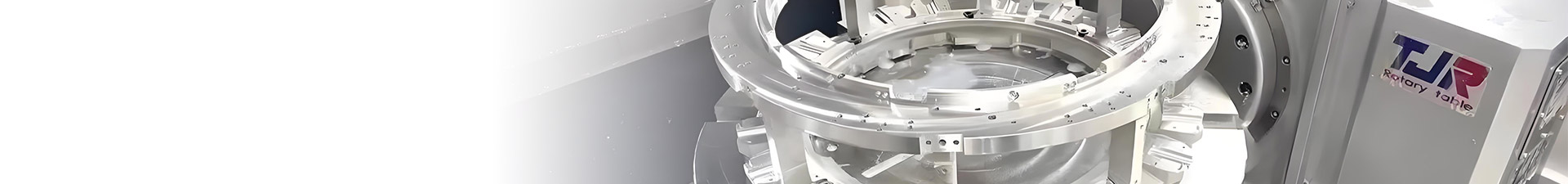

Characteristics of large gantry CNC machining machine models

Prev: Selection of Cooling Fluid and Analysis of Cooling Effect in Core Machining

Next: What is CNC machining? Overview of CNC machining process

Prelucrare CNC pe cinci axe, prelucrare CNC de precizie, prelucrarea strungului, Prelucrare de strunjire și frezare, frezare prelucrare pe cinci axe

Prelucrare CNC pe cinci axe, prelucrare CNC de precizie, prelucrarea strungului, Prelucrare de strunjire și frezare, frezare prelucrare pe cinci axe