The commonly used processing methods include CNC computer gong processing, large CNC lathe processing, large CNC gantry milling processing, large boring machine processing, large grinding machine processing, large planer processing, etc. Due to stable machining quality, high machining accuracy, high repeatability, and the difficulty of processing complex surfaces through conventional methods, large-scale CNC lathe machining has become a trendsetter in machining.

Large CNC lathe machining has become a benchmark for machining:

With the advancement of large-scale CNC lathe machining technology, composite machining technology has become increasingly mature, including milling and turning composites, turning and milling composites, turning boring and drilling gear machining, turning and grinding composites, forming composite machining, special composite machining, etc. The accuracy and efficiency of composite machining will be greatly improved.

2/New breakthroughs have been made in intelligent technology for large-scale CNC lathe machining, reflected in the performance of the CNC system. The automatic adjustment function for interference and collision prevention, automatic exit of the workpiece from the safe zone after power failure, power-off protection function, detection and automatic compensation learning function for machined parts, intelligent parameter selection function for high-precision machined parts, and automatic elimination of machine tool vibration during the machining process have entered the practical stage. Intelligence has improved the functionality and quality of machine tools.

3/New progress has been made in precision machining technology for large CNC lathes. The machining accuracy of CNC metal cutting machines has been improved from the original wire level to the micrometer level. By optimizing the structural design of machine tools, ultra precision machining and precision assembly of machine tool parts are carried out. High precision fully closed-loop control and dynamic error compensation technologies such as temperature and vibration are adopted. After the geometric accuracy of machine tool machining is improved, the form and position errors are reduced, and the surface roughness is reduced, thus entering the era of sub micron and nanometer level ultra precision machining.

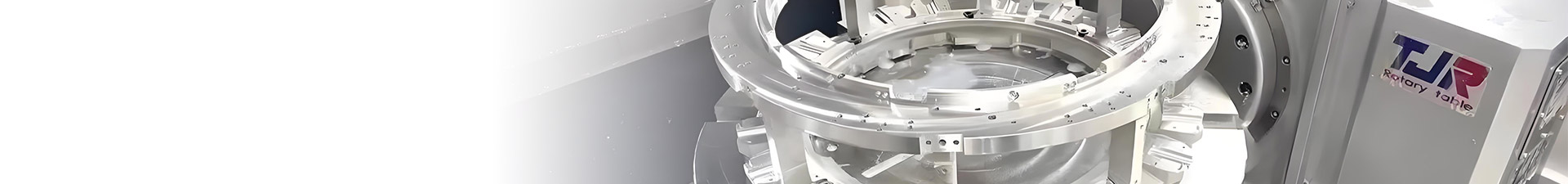

4/The performance of functional components of large CNC lathes continues to improve, and functional components are developing towards high speed, high precision, high power, and intelligence, achieving mature applications.

With the continuous improvement of equipment performance and the advancement of processing technology, large CNC lathes are favored by many mechanical processing plants. In terms of the choice of mechanical processing methods, more mechanical processing factories will tend to choose large CNC lathe processing, and large CNC lathe processing has become the benchmark for mechanical processing.