Numerical control lathes control cutting tools on workpieces through digital control systems, and can process various types of components. CNC lathes are mainly used in the mechanical manufacturing industry and can process various metal and non-metal materials, including iron, aluminum, copper, steel, stainless steel, plastic, cast iron, and other materials.

CNC lathes are widely used in aerospace, automotive, shipbuilding, rail transportation, electronics, communication, instrumentation, military and other fields. They can process various shapes of parts, such as shaft parts, disc parts, sleeve parts, flange parts, threaded parts, etc.

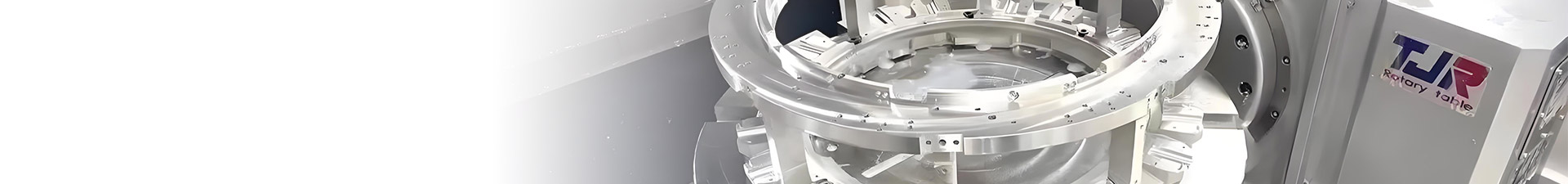

Numerical control lathes can complete precision machining operations such as turning, boring, internal and external grooves, threading, cylindrical, conical, and curved shapes. By adjusting different cutting tools and process parameters, the machining requirements of different components can be met, with advantages such as high precision, high efficiency, and good stability.